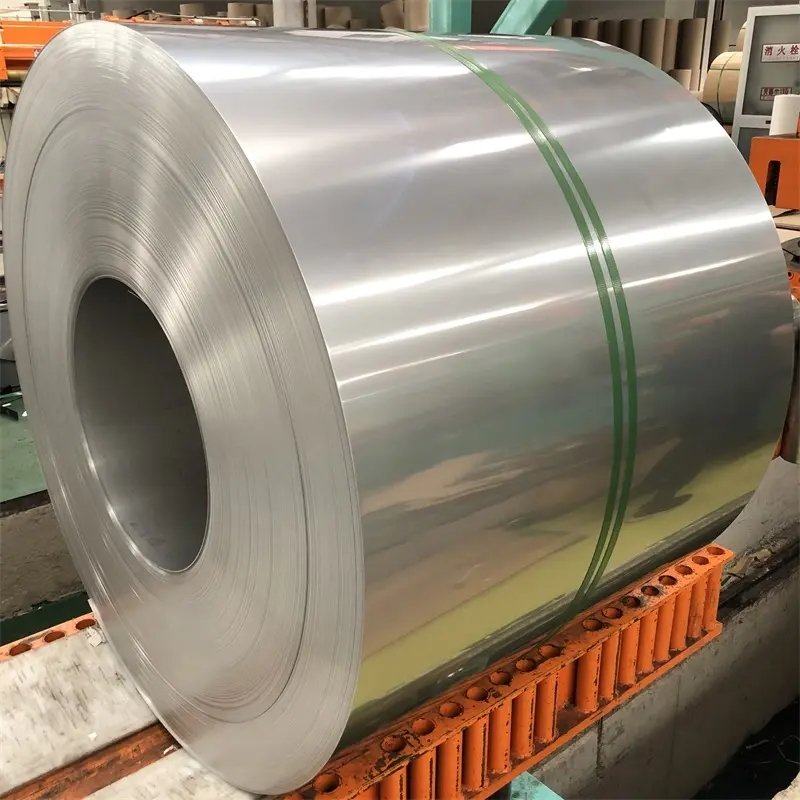

HL 304/201 Stainless Steel Coil

Key Features:

High-Quality Material: Made from superior raw materials, ensuring durability and performance.

Versatility: Ideal for fabricating pipes, tubes, and sheets.

Precision: Ensures accurate dimensions and uniform thickness.

Durability: Resistant to corrosion and wear, providing long-lasting performance.

Product Details

Product Description

HL stainless steel coils are among the most widely used types of metal coils in the market, primarily utilized for making pipes, tubes, and sheets. These stainless steel coils are manufactured using various raw materials and advanced technology, ensuring high quality and reliability for diverse applications.

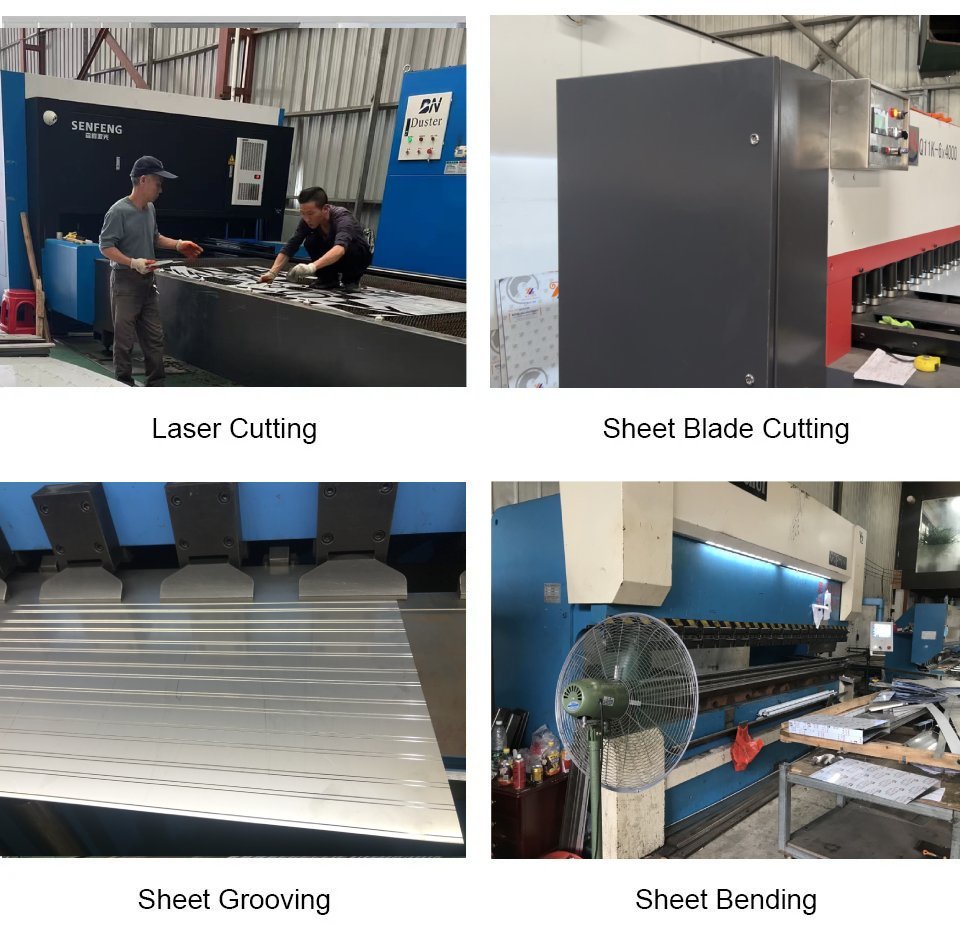

Manufacturing Processes:

Hot Rolling:

Description: The most common process for producing stainless steel coils involves heating the material to high temperatures and rolling it to achieve the desired thickness. This method produces large-sized coils with uniform thickness, size, and shape, making it suitable for high-volume production.

Cold Rolling:

Description: Conducted under controlled conditions to maintain product quality, cold rolling involves three stages: roughing pass (first pass), semi-finishing pass (second pass), and finishing pass (third pass). This method results in products with high dimensional accuracy, a smooth surface finish, and low yield loss due to reduced friction during rolling.

Extrusion:

Description: This process forms stainless steel into specific shapes by forcing it through a die, ensuring precise dimensions and consistent quality in the final product.

Application Scenarios

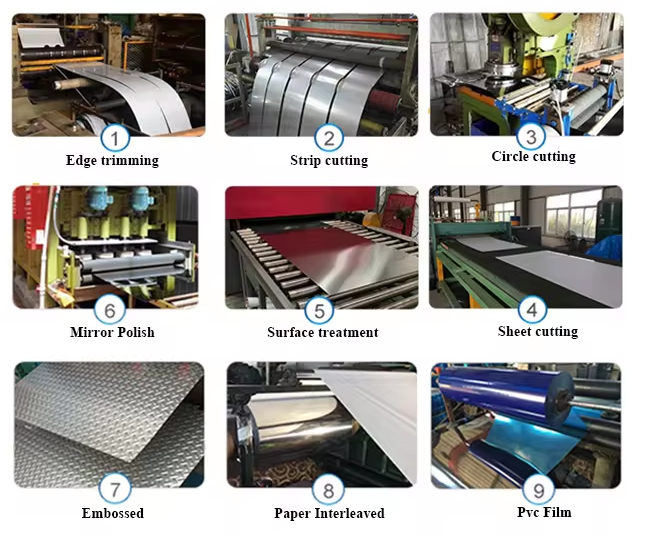

Additional Services